Case Coding Labelling Details

Click on the reference for details

Videojet® 2300 Series

Consistent print quality protects supply chain integrity:

- Patented Micropurge process automatically purges ink in programmable intervals to help keep the printhead free of dust and debris, helping to ensure the best print quality

- Scannable bar codes can be printed on-demand, including GS1 standards for ITF-14 and Code 128

- Videojet pigmented inks, available in a variety of colors, provide good edge acuity

Uptime Advantage and built-in productivity save time and money:

- Begin printing within one minute of powering up for quick daily startups

- Micropurge process and fluid container design help ensure very high ink utilization, minimizing ink waste and mess, while saving money

- Print density can be optimized on a per job basis to optimize operating costs and to allow standardization on one printer type for both high and moderate print quality applications

Simple Usability keeps operators focused on production, not the printer:

- Printer can operate in standalone mode using intuitive interface or be networked to PLCs or factory management systems for centralized control

- Data interfaces include Ethernet, RS232, USB, select ZPL command emulation, and text communication

- Connect packaging and printer controllers for web browser functionality of standalone machines

- Master/slave functionality allows up to four printheads to be controlled from one controller for more efficient job management

Seamless integration with other Videojet products:

- Single point message selection is delivered to multiple devices

- CLARiNET® software connects all Ethernet devices, scanners, throughout the production floor

Videojet® 2120

Application coverage on demanding surfaces:

- Inks are quality engineered for lasting codes on a variety of products and surfaces

- Compact printhead design allows for easy integration into existing conveyance systems

- Advanced printhead slant control technology allows the printhead to be mounted at an angle so the text message style, density and height can be matched to the case design

Built-in color touchscreen makes operator intervention easy:

- Onscreen editor allows you to create and edit messages on the fly

- Onscreen indicators report ink use, job status, message preview, counts and other production details at a central location for controlling and interacting with the printer

- Control and access can be limited with passwords to help ensure your production continues unimpeded

Simple Usability keeps operators focused on production, not the printer:

- Built-in configuration wizard shortens system setup time by guiding the operator through the installation process

- Printer can operate in standalone mode using intuitive interface or be networked to PLCs or factory management systems for centralized control

- Communication protocols include Ethernet, RS232 and USB to match your operating requirements

- Print data can be encoded as ZPL or text communication

- Connect packaging and printer controllers for web browser functionality of standalone machines

- Master/slave functionality allows up to four printers to be controlled from one controller for more efficient job management

Seamless integration with other Videojet products validates matching codes factory wide:

- Single point message selection is delivered to multiple devices

- CLARiNET® software connects all Ethernet devices, including scales and scanners, throughout the production floor

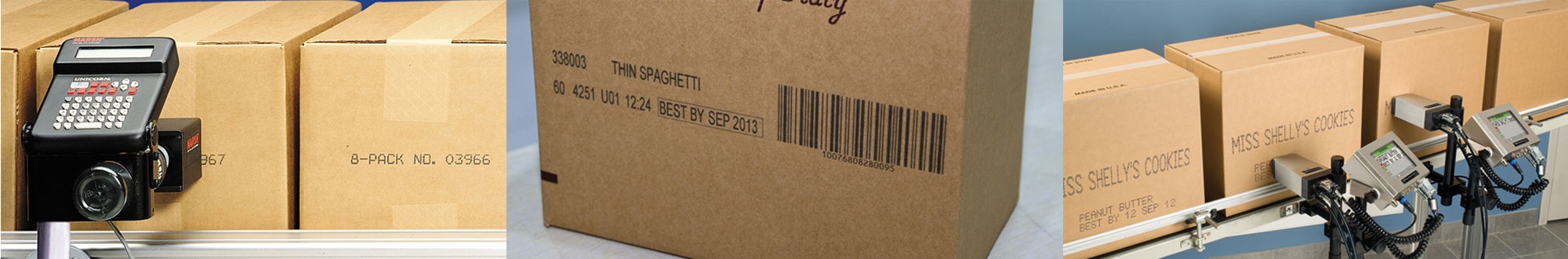

Unicorn II

Compact, self-contained design makes coding easy:

- Quick and simple integration; out of the box and on the job in minutes

- Includes a standalone bracket minimizing hardware integration needs

- Built-in photocells detect production direction and speed for simple integration

- Menu-driven controller to create and edit messages

Unicorn offers the most economical case coding solution:

- Low acquisition cost to deliver on-demand case coding to nearly all simple applications

- Low consumable cost keeps per item coding cost low for profitable operations

- Optional bulk ink supply further reduces consumable costs and extends time between ink reloads for more efficient operation

Rich features enable broad application coverage:

- Choice of single (Unicorn) and single/dual line (Unicorn II) coding

- Customized time, date and count codes including best before/best by date which automatically update for minimal operator interaction

- Universal voltage and built-in language selection for global use

- Stores messages in the controller for instant recall to reduce time to complete line change over

Do you want to get more information about our products?