Continuous Ink Jet Printers Description

Click on the reference for ink jet printers 1000 series line platform details

The Videojet 1000 Series ink jet Printers New Generation: Boost your productivity!

Boost your productivity with technology …

It is time to change your mind about what industrial ink jet printers can provide. New continuous ink jet printers Videojet 1000 Series are designed and studied so your production line remains operational for longer.

-

The efficiency and availability of your production lines,

-

A visible advantage in terms of print quality,

-

A simple and predictive maintenance

-

Simplicity and reliability in all circumstances

- No dirt, no waste, no error,

Videojet 1220

Speed without compromising quality:

- Ideal solution for a range of slow to moderate speed applications:

- Single line maximum speed of 162 m/min (533 ft/min)

- Two line maximum speed of 59 m/min (194 ft/min)

- Three line maximum speed of 29 m/min (96 ft/min)

- Store up to 100 complex messages for easy recall. Store even more messages using a standard USB memory stick

- Small and portable, the 1220 ink jet printer is easily moved from line to line with minimal connections

Engineered to keep your line running:

- Videojet’s advanced core technology includes all ink system filters and common wear parts

- Intervals of up to 9,000 hours between preventative maintenance

- Auto cleaning printhead for fast start-ups, even after extended shutdowns

- Optional internal air pump eliminates need for external air, minimizing potential for contaminants to enter the ink stream

No mess, no waste fluid delivery:

- Advanced fluid management reduces makeup consumption to as low as 2.4 ml/hr

- Smart CartridgeTM fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

Simple Usability via Videojet standard CIJ interface:

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and maintenance

- Prompted user fields to help reduce errors

Videojet 1520

High quality print at speeds for a range of applications:

- Dynamic Calibration™ adjusts jetting parameters automatically to help ensure high quality print

- Print 1 to 5 lines of print for a range of coding needs:

- Single line max speed = 279 m/min (914 ft/min)

- Dual line max speed = 81 m/min (267 ft/min)

- Tri-line max speed = 36 m/min (119 ft/min)

Engineered for extended runs; Uptime Advantage via:

- CleanFlow™ technology resists ink buildup that can cause ordinary ink jet printers to shut down

- Long run time between preventive maintenance; up to 12,000 hour core life

- Internal pump means no external air, minimizing potential for contaminants to enter ink stream

- Auto cleaning printhead for fast start-ups, even after extended shutdowns

No mess, no waste fluid delivery:

- Make-up consumption as low as 2.4 ml/hour

- Smart Cartridge™ fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

Simple Usability via Videojet standard CIJ interface:

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and maintenance

- Prompted user fields to help reduce coding errors

Videojet 1550

The 1550 ink jet printers are a highly flexible printer designed for a range of packaging applications. Engineered to provide the highest uptime available, the 1550 meets a range of medium-duty coding applications and also includes advanced features that help reduce errors and rework and improve productivity.

The 1550 ink jet printers are a highly flexible printer designed for a range of packaging applications. Engineered to provide the highest uptime available, the 1550 meets a range of medium-duty coding applications and also includes advanced features that help reduce errors and rework and improve productivity.

Code Assurance features help eliminate common coding errors by helping your operators put the right code on the right product, time after time. On-board Productivity Tools display details about both Printer Availability and Operational Availability, enabling a review of data to discover technical and operational causes of unplanned downtime. This data is presented in a logical way to help identify the root cause of downtime, and empower operators to take corrective action and boost productivity.

Videojet® 1580 Industrial Inkjet Printer

Videojet® 1580 Industrial Inkjet Printer

Continuous inkjet printer to help enhance everyday performance

The Videojet 1580 Continuous Inkjet (CIJ) Printer delivers uptime peace of mind, and offers guidance to help ensure error-proof operation by utilizing individual printer consumption to assess and offer improvements about the way you use your printer. Videojet OPTIMiZE provides on-screen alerts with expert diagnostics, analytics and guides to enhance everyday printer performance.

The Videojet SIMPLICiTY™ interface reduces operator printer interactions, helping to eliminate potential user errors through an intuitive, tablet-inspired 10-inch touchscreen display.

Videojet SmartCell™ components are quick and easy-to-replace within minutes, helping to ensure you receive maximum line productivity and no additional downtime.

Benefit from increased uptime with optional CleanFlow™ technology, designed to resist ink build-up and result in less cleaning, enabling longer runs and delivering consistent print performance with minimal operator intervention.

Videojet 1620

Capabilities to meet your fast production lanes:

- Dynamic Calibration™ adjusts jetting parameters automatically to help ensure high quality print

- Print from 1 to 5 lines of text at high speeds:

- Single line max speed = 293 m/min (960 ft/min)

- Dual line max speed = 146 m/min (480 ft/min)

- Tri-line max speed = 81 m/min (265 ft/min)

Engineered for extended runs; Uptime Advantage via:

- CleanFlow™ technology resists ink buildup that can cause ordinary ink jet printers to shut down

- Long run time between preventive maintenance; up to 14,000 hour core life

- Internal pump means no external air, minimizing potential for contaminants to enter ink stream

- Auto cleaning printhead for fast start-ups, even after extended shutdowns

No mess, no waste fluid delivery:

- Make-up consumption as low as 2.4 ml/hour

- Smart Cartridge™ fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

Simple Usability via Videojet standard CIJ interface:

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and maintenance

- Prompted user fields to help reduce coding errors

Videojet 1620 UHS

Speed without compromising quality:

- Videojet’s Precision Ink Drop™ system provides precise character formation, even at the highest speeds and longer throw distances

- Dynamic Calibration™ adjusts jetting parameters automatically to help ensure high quality print

- Superior technology enables you to add content without compromising speed

- Single line max speed = 508 m/min (1666 ft/min)

- Dual line max speed = 212 m/min (694 ft/min)

- Tri-line max speed = 179 m/min (588 ft/min)

Engineered for extended runs:

- CleanFlow™ technology resists ink buildup that can cause ordinary ink jet printers to shut down

- Long run time between preventative maintenance; up to 14,000 hour core life

- Internal pump means no external air, minimizing potential for contaminants to enter ink stream

- Auto cleaning printhead for fast start-ups even after extended shutdowns

No mess, no waste fluid delivery:

- Make-up consumption as low as 2.4 ml/hour

- Smart Cartridge™ fluid delivery system to virtually eliminate spills and ensures the correct fluids are being used

Simple Usability via an advanced user interface:

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and maintenance

- Prompted user fields to help reduce coding errors

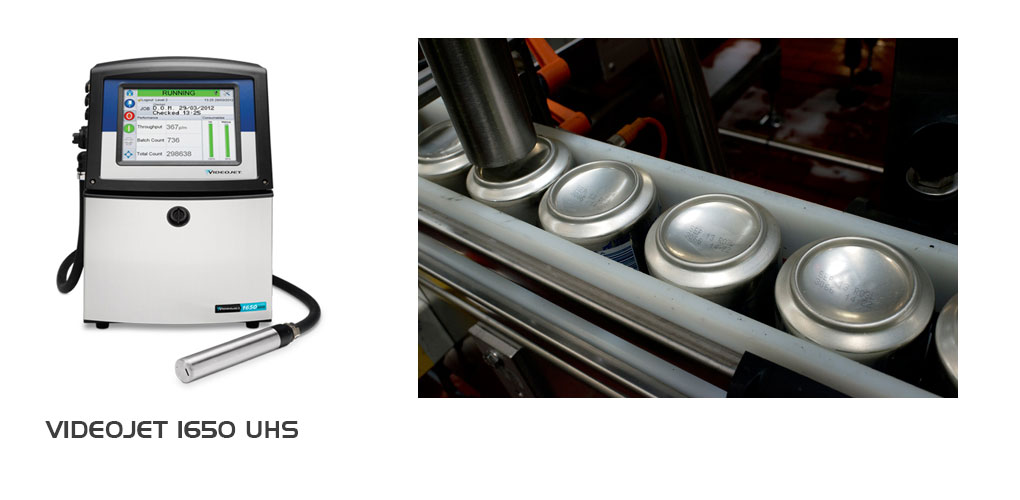

Videojet 1650

The Videojet 1650 continuous ink jet printers are engineered for more demanding coding and marking applications where a combination of speed and throughput require a high utilization solution. In addition to delivering an Uptime Advantage, the 1650 provides advanced features to help reduce operator error and tools to help improve Overall Equipment Effectiveness (OEE).

Code Assurance features help eliminate common coding errors by helping your operators put the right code on the right product, time after time. On-board Productivity Tools display details about both Printer Availability and Operational Availability, enabling a review of data to discover technical and operational causes of unplanned downtime. This data is presented in a logical way to help identify the root cause of downtime, and empower operators to take corrective action and boost productivity and profits.

Speed without compromising quality:

- Dynamic Calibration™ adjusts jetting parameters automatically to help ensure high quality print

- Print from 1 to 5 lines of text at high speeds:

- Single line max speed = 293 m/min (960 ft/min)

- Dual line max speed = 146 m/min (480 ft/min)

- Tri-line max speed = 81 m/min (265 ft/min)

Engineered for extended runs; Uptime Advantage via:

- CleanFlow™ technology resists ink buildup that can cause ordinary ink jet printers to shut down

- Long run time between preventive maintenance; up to 14,000 hour core life

- Internal pump means no external air, minimizing potential for contaminants to enter ink stream

- Auto cleaning printhead for fast start-ups even after extended shutdowns

No mess, no waste fluid delivery:

- Make-up consumption as low as 2.4 ml/hour

- Smart Cartridge™ fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

On-board Code Assurance to help prevent coding mistakes:

- Advanced software minimizes and mistake-proofs operator inputs to the coding and marking process to help reduce errors

- Operator inputs are governed by rules which simplifies choices via field prompts, drop-down menus, calendar displays and predefined formats to help ensure correct entries

Built-in Productivity tools to keep your lines operational:

- Bright, 264 mm (10.4 in) touchscreen interface that provides real-time fluid levels, maintenance alerts, print jobs and other operational information

- Instant fault information is displayed to get your printer and line running again – fast

- Drill down into Printer Availability data to discover technical and operational causes of downtime, get to the root cause of downtime events and fix them for good

Videojet 1650 UHS

The Videojet ink jet printers 1650 UHS offers all of the benefits of the 1620 UHS plus the following advanced features:

- On-board Code Assurance to help prevent coding mistakes

- Advanced software minimizes and mistake-proofs operator inputs to the coding and marking process to help reduce errors

- Operator inputs are limited to specified choices, with field prompts, drop-down menus, calendar displays and predefined formats to help ensure correct entries

Built-in Productivity tools to keep your lines operational:

- Bright, 264 mm (10.4 in) touchscreen interface that provides real-time fluid levels, maintenance alerts, print jobs and other operational information

- Instant fault information is displayed to get your printer and line running again – fast

- Drill down into Printer Availability data to discover technical and operational causes of downtime, get to the root cause of downtime events and fix them for good

Videojet 1610 DH

Speed without compromising quality:

- Dynamic Calibration™ adjusts jetting parameters automatically to help ensure high quality print

- Dual printheads enable high speed printing of up to 10 lines of text with single printhead speed performance:

- Single line max speed = 293 m/min (960 ft/min)

- Dual line max speed = 146 m/min (480 ft/min)

- Tri-line max speed = 81 m/min (265 ft/min)

Engineered for extended runs; Uptime Advantage via:

- CleanFlow™ technology resists ink buildup that can cause ordinary ink jet printers to shut down

- Long run time between preventive maintenance; up to 12,000 hour core life

- Internal pump means no external air, minimizing potential for contaminants to enter ink stream

- Auto cleaning printhead for fast start-ups, even after extended shutdowns

No mess, no waste fluid delivery:

- Make-up consumption as low as 2.4 ml/hour

- Smart Cartridge™ fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

Simple Usability via Videojet standard CIJ interface:

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and maintenance

- Prompted user fields to help reduce coding errors

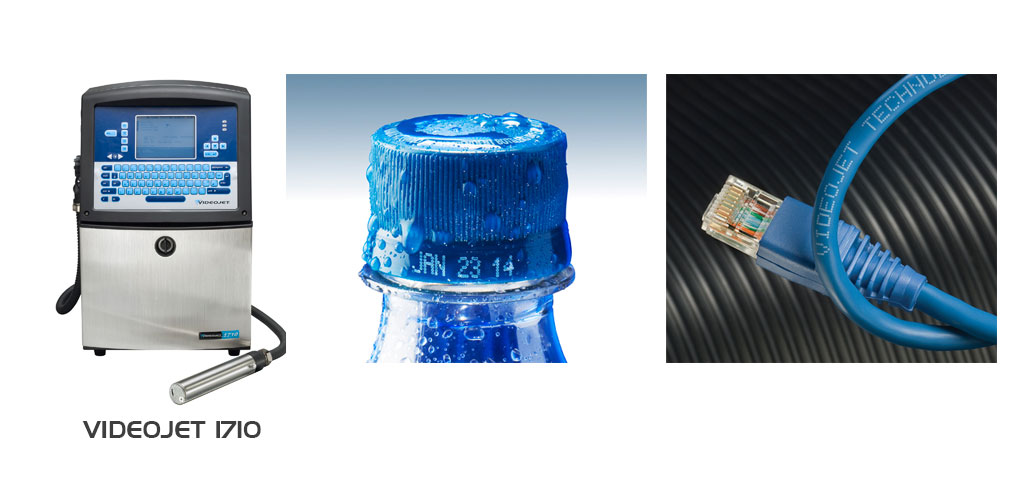

Videojet 1710

Capabilities to meet your fast production lanes:

- Dynamic Calibration™ adjusts jetting parameters automatically to ensure high quality print

- The unique fluid system assures proper dispersion of pigments while printing, or when idle for long periods of time

- Print from 1 to 5 lines of text at high speeds:

- Single line max speed = 271 m/min (888 ft/min)

- Dual line max speed = 122 m/min (400 ft/min)

- Tri-line max speed = 67 m/min (221 ft/min)

Engineered for extended runs; Uptime Advantage via:

- CleanFlow™ technology resists ink buildup that can cause ordinary ink jet printers to shut down

- New conical ink reservoir minimizes natural effects of pigment settling

- Long run time between preventive maintenance; up to 4,000 hour core life

- Internal pump means no external air, minimizing potential for contaminants to enter ink stream

- Auto cleaning printhead for fast start-ups even after extended shutdowns

No mess, no waste fluid delivery:

- Innovative fluid management system simply and reliably delivers ink to the products you need coded without significant operator intervention

- Smart Cartridge™ fluid delivery system to virtually eliminate spills and help ensure the correct fluids are being used

Simple Usability via Videojet standard CIJ interface:

- Bright display with WYSIWYG and function keys for easy operation

- User levels to separate operation from installation and maintenance

- Prompted user fields to help reduce coding errors

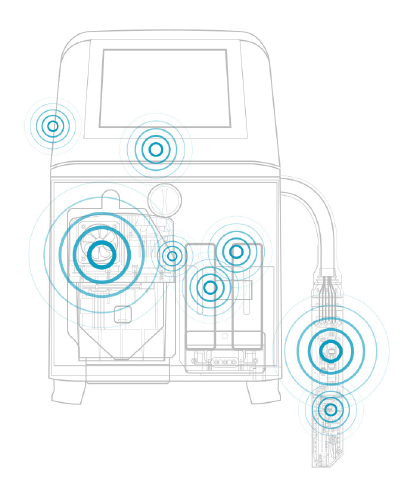

Putting the continuous into continuous inkjet

The printer has been designed to deliver industry first predictive capability providing superior uptime and performance. The result is a revolutionary design that achieves your marking and coding objectives

today and as they evolve.

Industry first predictive ink build-up sensor

Industry first predictive ink build-up sensor

Significantly reduce the main cause of unplanned printer downtime with an industry first ink build-up sensor. The 1860 printhead incorporates a unique sensor which enables the printer to detect build up in the printhead, alerting the user with advanced notification before print clipping and the associated EHT trips occur.

Continuously monitor your 1860 printer’s health

Powerful on-board intelligence runs through a revolutionary system, with 53 sensors continuously monitoring over 150 key indicators of printer performance, providing expert diagnostics, analytics and guiding you to correct problems before they happen.

Make up reserve tank with a minimum 8 hours of run time*

An additional reserve tank protects production under normal operating conditions – allowing ample

advance warning to prevent a downtime event.

Precise fluid transfer measurement increases the stability of the ink and make-up mix, and provides reliable indication of remaining fluid levels. The 1860’s fluid system features a larger 1 litre Smart Cartridge™ with the Videojet embedded microchip, ensuring only compatible fluids are used. Loading the wrong ink or an

incompatible make-up fluid is impossible, helping prevent common operator mistakes.

*Under normal operating conditions

ink jet printers from Videojet : The full print without contact

Contactless coding

The inkjet printers are based on various technologies. According to them, they are used for marking small or large print. The technique of continuous deflected ink jet is mainly used in the industry for small type.The so-called “drop on demand” printing method can be divided into three variants: the piezoelectric pulse technology Solenoid and Bubble Jet. Following these variants, small and / or large print can be printed.

Technique of continuous inkjet

In the case of the technique of continuous deflected ink jet printed characters are produced by individual ink drops. The movement of product on the production line is operated to print the letters or numbers one after the other on the product surface. It is a process without contact with the product. Today, this marking technique is mainly used to print expiration dates, such as those on the yogurt cups, bottles and cans.

Fragmentation into separate droplets

The ink jet emerges from the printhead through a nozzle whose diameter varies with the size of the droplets and thus the desired print.An ultrasound signal is sent at a fixed frequency to a piezo crystal located at the back of the nozzle and the ink jet breaks into a plurality of drops. Depending on the voltage applied to the crystal, the ink jet, as initially undivided stream is converted into individual ink drops.

Recycling unused ink

When the drops come out of the tunnel load, they pass under a spoiler.Positively charged, this plate attracts negatively charged ink drops and deviates from their initial trajectory. The degree of deviation depends on the level of negative charge drops of ink: the larger the load, the greater the deviation will be. Uncharged drops it continues on their straight trajectory towards the block back and are reinstated in the ink module to be reused.

From the inkdrop to the text

Fonts are composed of a matrix of vertical segments corresponding to the ink drops. For example, five vertical segments, each with a height of up to seven drops of ink, are a character in a font based on a 5 x 7 matrix. The charge level of a drop of ink determines its position in the vertical segment. By moving the printing surfaces, the printer ensures horizontal alignment segments, according to a also controlled automatically pace.

Drop on demand

With the technique of drop on demand, unlike the ink jet technique, only necessary to print drops are produced. With the technique of the continuous deflected ink bubble is used in water-based ink. The water is heated until bubbles form. The ink is then conveyed into the nozzles in the form of tiny bubbles. With piezo technology, a voltage is applied to the piezoelectric crystals. This voltage induces an expansion of the crystals, which eject the printing ink from the nozzle. The drop volume is controlled by electrical impulses. printers to solenoid valves are used only in industrial applications. Valves, incorporated in nozzles are opened only when the ink droplets are ejected from the nozzle.

- No clogging of nozzles with a continuous flow of ink – Marking fast drying – High Speed - Suitable for marking small characters – High resolution

Do you want to get more information about our products?