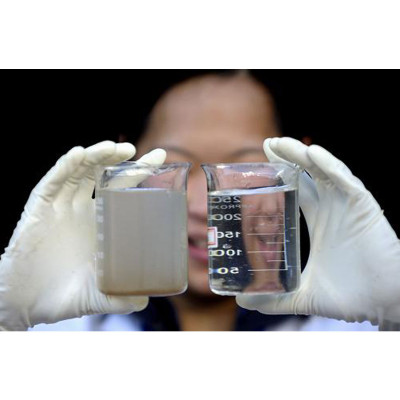

Problems encountered in DHW systems are often revealed, well before leaks occur, by coloured water being drawn off (reddish-ochre for galvanised steel systems and blue-green for copper systems).

The treatment applied, whether to prevent scaling or corrosions, must enable water quality to be maintained in compliance with the applicable standards which define the composition of water for human consumption.